One minor change coming to USP 795 could make a major difference in the way pharmacies perform reconstitution.

USP is in the process of revising parts of USP 795, the general chapter on compounding non-sterile medications. Among other changes, the revisions clarify one of the most highly debated and important issues in the compounding world.

“Considering safety and standardization is at the forefront of compounding discussions, water quality is a hot topic right now in the world of pharmacy,” said Dr. Ursula Chizhik, PharmD, VP of quality and regulatory affairs at FLAVORx, a company that provides a flavoring system for pharmacies to personalize medication for patients. “While water quality and its specifications have always been more stringent and of greater concern in the sterile compounding space, we are seeing this focus trickle into the nonsterile compounding world as well.”

USP has always required the use of purified water for non-sterile compounding but not necessarily for reconstitution. The water requirements for reconstitution depended on whether it was considered non-sterile compounding, which until now has been unclear and left to the decision of each state’s board of pharmacy.

But the new revisions erase the distinction between the two. In addition, the new rules explicitly require purified water for all reconstitutions, which “has never been as boldly and directly stated,” Chizhik said.

The revision reads: “Purified water, or an equivalent quality of water, must be used to reconstitute conventionally manufactured nonsterile products when water quality is not stated in the manufacturer’s labeling.”

The new requirement aims to improve quality, consistency, and safety for all compounding purposes. Without these revisions, it’s nearly impossible to ensure consistent water use across all pharmacies.

“Since source water or influent water varies from state to state or even sometimes from county to county and region to region, it is very difficult to say that water from one location is comparable to water from another location,” Chizhik said. “Varying water quality can ultimately vary the final product. For this reason, USP 795 wants to ensure that proper water is being used across the industry and to emphasize the importance of promoting consistent product from pharmacy to pharmacy and from dispenser to dispenser.”

What this means for pharmacy

With this new focus on water quality, pharmacies might start facing stricter water inspections. It’s become more common for FDA and boards of pharmacy inspectors to scrutinize water quality more closely, including checking for routine maintenance of filtration systems and testing conductivity of effluent water, according to Chizhik.

“Considering the increased emphasis on compounding safety, USP, FDA, states, and accreditation organizations are coming down on pharmacies, pharmacists, and pharmacy technicians to make sure they are complying with current best practices,” she said.

And chances are, many pharmacies aren’t complying—whether they realize it or not. Chizhik said pharmacies commonly fail to verify the purity of their water. Instead, they simply rely on distilled water jugs, purified boxed water, or “acceptable” purifying processes like in-line filtration or reverse osmosis filters.

“We are assuming the water that we are using is safe and meets the parameters, rather than testing to be sure the water is safe and meeting parameters,” she said. “Part of standardization and the focus on standardization is having metrics and measurements and criteria that can be checked and verified over time.”

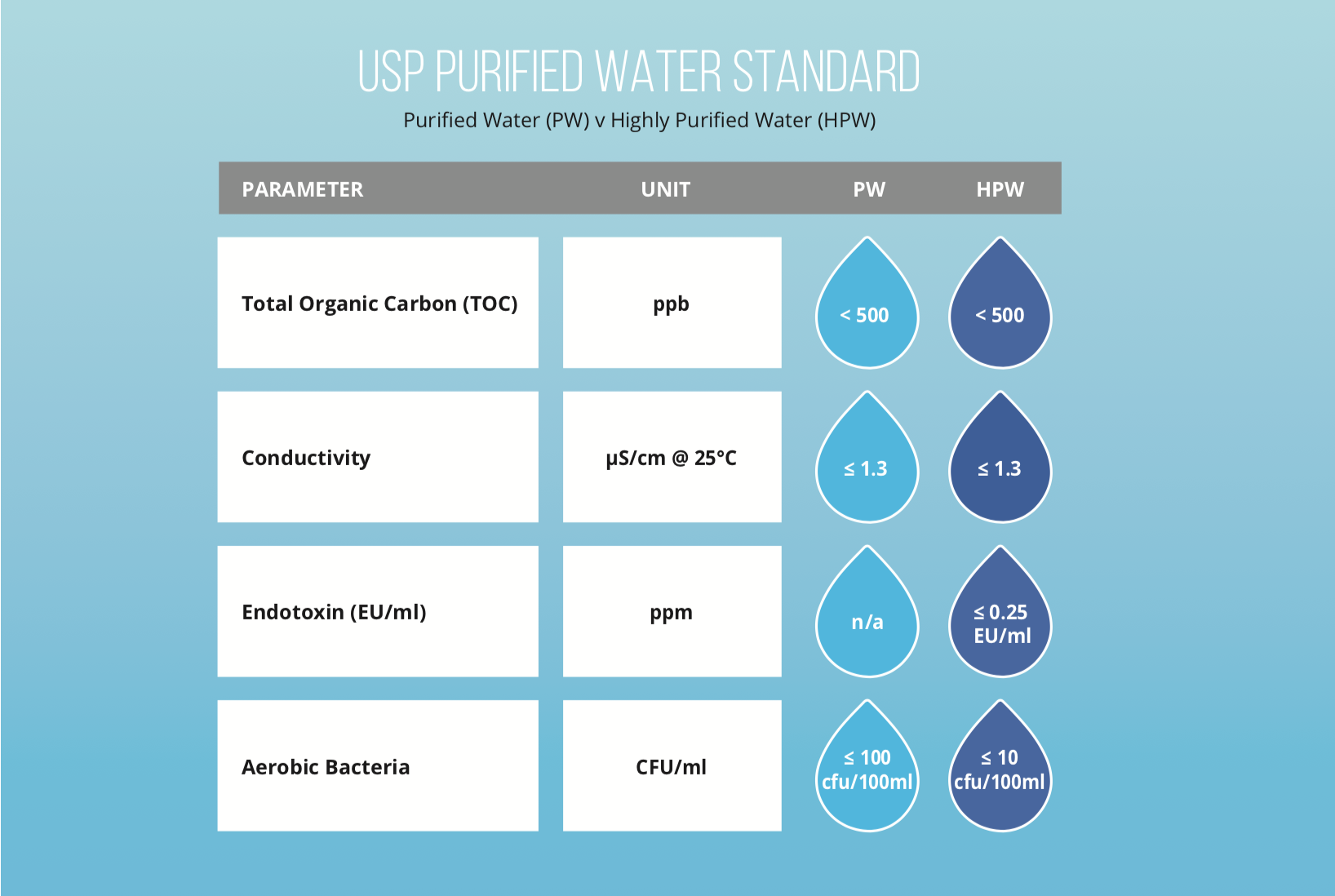

USP outlines specific chemical quantities required for water to be pure, specifically for conductivity, total organic carbon, and bacteria. And those numbers take discipline to meet and maintain. “Even a distilled jug of water, that is a commonly used method for reconstitution, is not able to maintain conductivity levels below 1.3 micro siemens per centimeter once the bottle has been opened and exposed to air over time,” Chizhik said.

How to ensure water purity

Methods for purifying water come a dime a dozen. But not all of them are up to par. “If you’re currently using bottled water or anything less than a six-stage reverse osmosis system, you’re probably not meeting USP standards,” Chizhik said. “While six stages of filtration may seem excessive, it has been our experience that to maintain designated specifications over time, this is a reliable method.”

The six-stage reverse osmosis system not only ensures water meets specification, but it’s also more cost-effective and easier to maintain than the other popular methods. One of the national chain pharmacies recently committed to using this system to ensure it meets USP standards, Chizhik said.

“Pharmacies all across the country, from national chains to independents, are taking water quality more seriously and taking proactive steps to ensure USP standards are met for all of their non-sterile compounding and reconstitution needs.”

The final revision of USP 795 will publish in 2019.

From the Magazine

This article was published in our quarterly print magazine, which covers relevant topics in greater depth featuring leading experts in the industry. Subscribe to receive the quarterly print issue in your mailbox. All registered independent pharmacies in the U.S. are eligible to receive a free subscription.

Read more articles from the December issue:

- The complete guide to CBD, the new profitable plant product sweeping the nation

- How to protect your patients from online pharmacy scams

- One simple solution to making more money from your front-end

- The latest independent pharmacy trends from 2018 NCPA Digest

- How to boost front-end revenue by engaging all five senses

- The guide to getting a loan from the experts who lend them out

- How one independent pharmacy thrives through nonprofit partnerships

A Member-Owned Company Serving Independent Pharmacies

PBA Health is dedicated to helping independent pharmacies reach their full potential on the buy-side of their business. Founded and run by pharmacists, PBA Health serves independent pharmacies with group purchasing services, wholesaler contract negotiations, proprietary purchasing tools, and more.

An HDA member, PBA Health operates its own NABP-accredited warehouse with more than 6,000 SKUs, including brands, generics, narcotics CII-CV, cold-storage products, and over-the-counter (OTC) products — offering the lowest prices in the secondary market.